Plastics are widely used in different industries for many reasons. They are durable and can last for a long time. They are also cost-effective and cheaper than other materials like wood, glass, and metal. Additionally, plastics take a long time to degrade, making them strong throughout their lifecycle.

LDPE plastic is a type of plastic that is highly valued in various industries.

What Is LDPE?

LDPE, which stands for low-density polyethylene, is a type of thermoplastic that is produced using the monomer ethylene.

Manufacturers commonly use LDPE in film applications due to its transparency, flexibility, and durability. They also use it to make various flexible bottles and lids, as well as cable and wire applications.

LDPE is a 100% recyclable thermoplastic polymer that is transparent, odorless, and commonly used in products like garbage and grocery bags, cling wraps, and juice containers. Its flexibility, toughness, and corrosion resistance, along with its low-cost and high-efficiency production process, make it an attractive option for engineering applications. This has led to a high demand for the production of thousands of tons of LDPE each year.

2 Common Types of PE

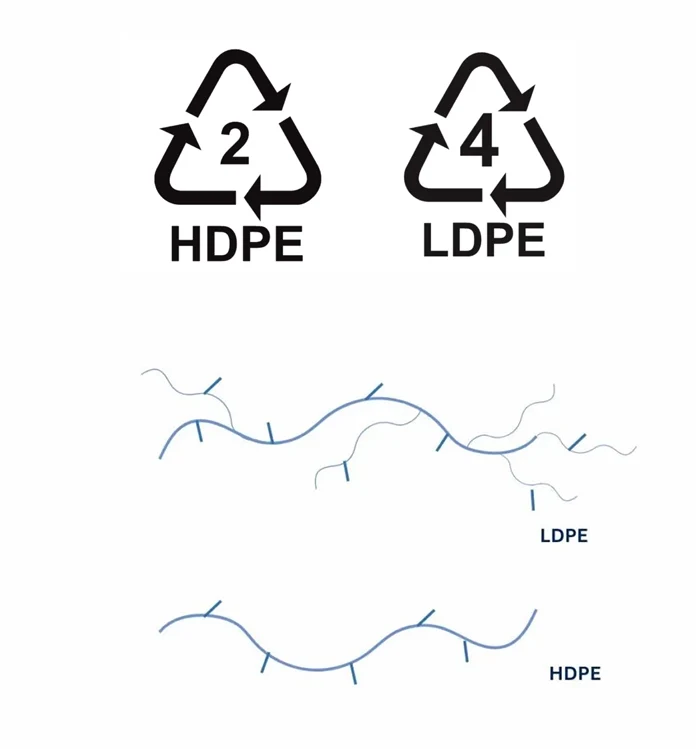

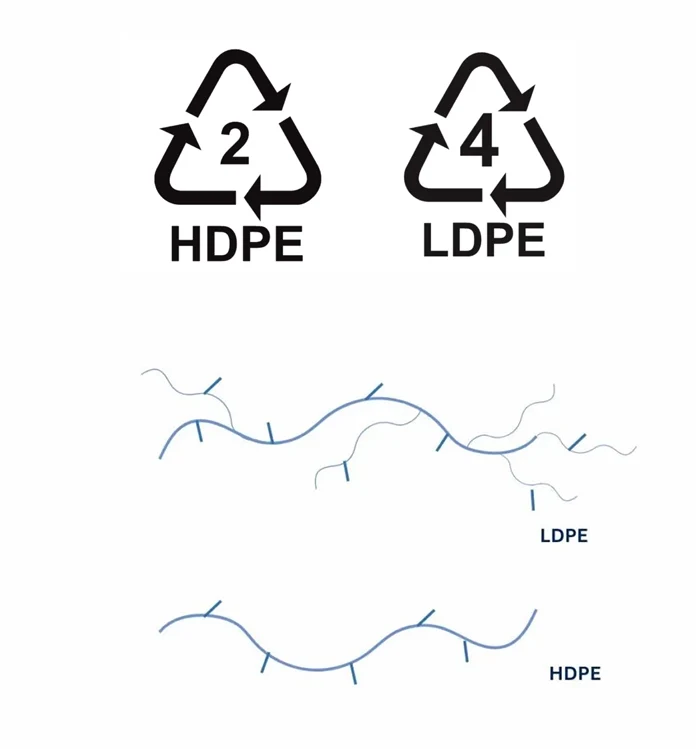

Polyethylene (PE) is a commonly used material in the film and flexible packaging industry. There are two primary types of PE used in this sector: Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE). HDPE is typically used for producing heavier-duty films such as long-life bags and sacks, protective sheeting, food bags, trays, and caps. On the other hand, LDPE is suitable for creating thin gauge carrier bags, fresh produce bags, and some bottles.

Additionally, there are various other types of PE available in the market, all offering exceptional moisture barrier and chemical resistance properties.

2 Common types of PE

Polyethylene (PE) is a commonly used material in the film and flexible packaging industry. There are two primary types of PE used in this sector: Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE). HDPE is typically used for producing heavier-duty films such as long-life bags and sacks, protective sheeting, food bags, trays, and caps. On the other hand, LDPE is suitable for creating thin gauge carrier bags, fresh produce bags, and some bottles.

Additionally, there are various other types of PE available in the market, all offering exceptional moisture barrier and chemical resistance properties.

Properties and Characteristics of LDPE

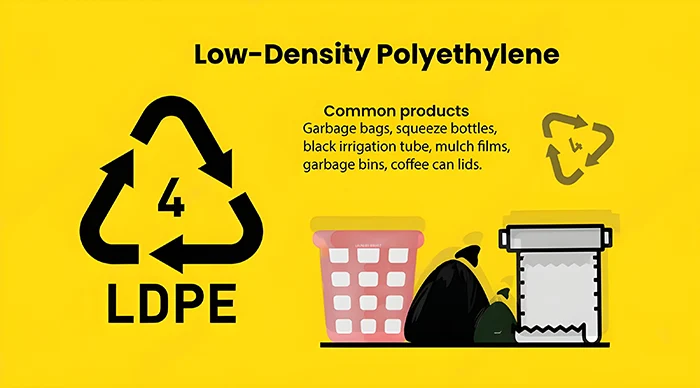

Low-Density Polyethylene (LDPE) is a flexible, odorless, transparent, and 100% recyclable thermoplastic polymer. It is the second most common type of polyethylene, with High-Density Polyethylene (HDPE) being the first. LDPE is identified by a number "4" within an arrow triangle on plastic products.

It is widely used in various applications due to its unique properties, such as:

Flexibility: LDPE is highly flexible and can withstand low temperatures, making it suitable for products like cling wrap, plastic bags, and food containers.

Toughness: Despite its flexibility, LDPE is also quite tough and resistant to impact, making it suitable for applications like pallet wrapping, pipes, and tubing.

Corrosion Resistance: LDPE offers good chemical resistance and is resistant to moisture, making it suitable for use in the agricultural and food industries.

Transparency: Companies and users popularly utilize this polymer for its transparency in packaging and film applications.

Branched structure: Polyethylene, a thermoplastic polymer, forms the basis of LDPE with long chains of ethylene molecules. The highly branched bonding structure of LDPE gives it unique properties. Therefore, due to its lower crystallinity, it has unique properties like flexibility and ductility. This makes LDPE quite different from more linear varieties of polyethylene like HDPE and linear low-density polyethylene (LLDPE).

Recyclability: Companies can use recycled LDPE to produce various products, such as piping, sheeting, films, and trash bags. These products find applications in composite lumber, building, and agriculture.

What is LDPE used for?

Low-density polyethylene (LDPE) is a type of plastic with properties that make it a popular choice for food-safe bagging, waterproof packaging, and other packaging materials. Its low density and high strength allow for the creation of thin sheets that can hold relatively high loads, something like grocery bags or soda-can six-pack rings.

Additionally, this versatile plastic can be found all over the world and is used by companies and individuals for various reasons. Some of its most common uses are mentioned below.

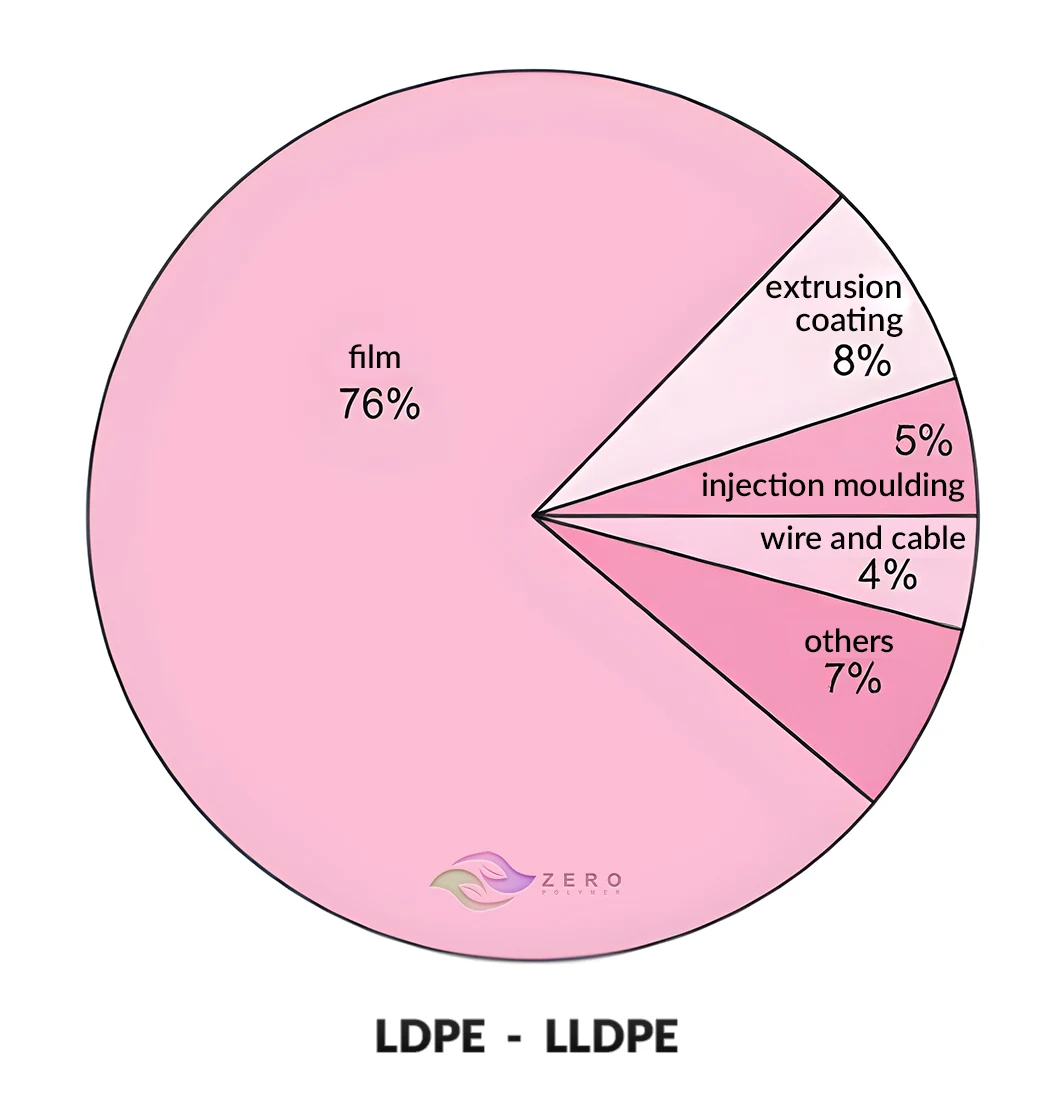

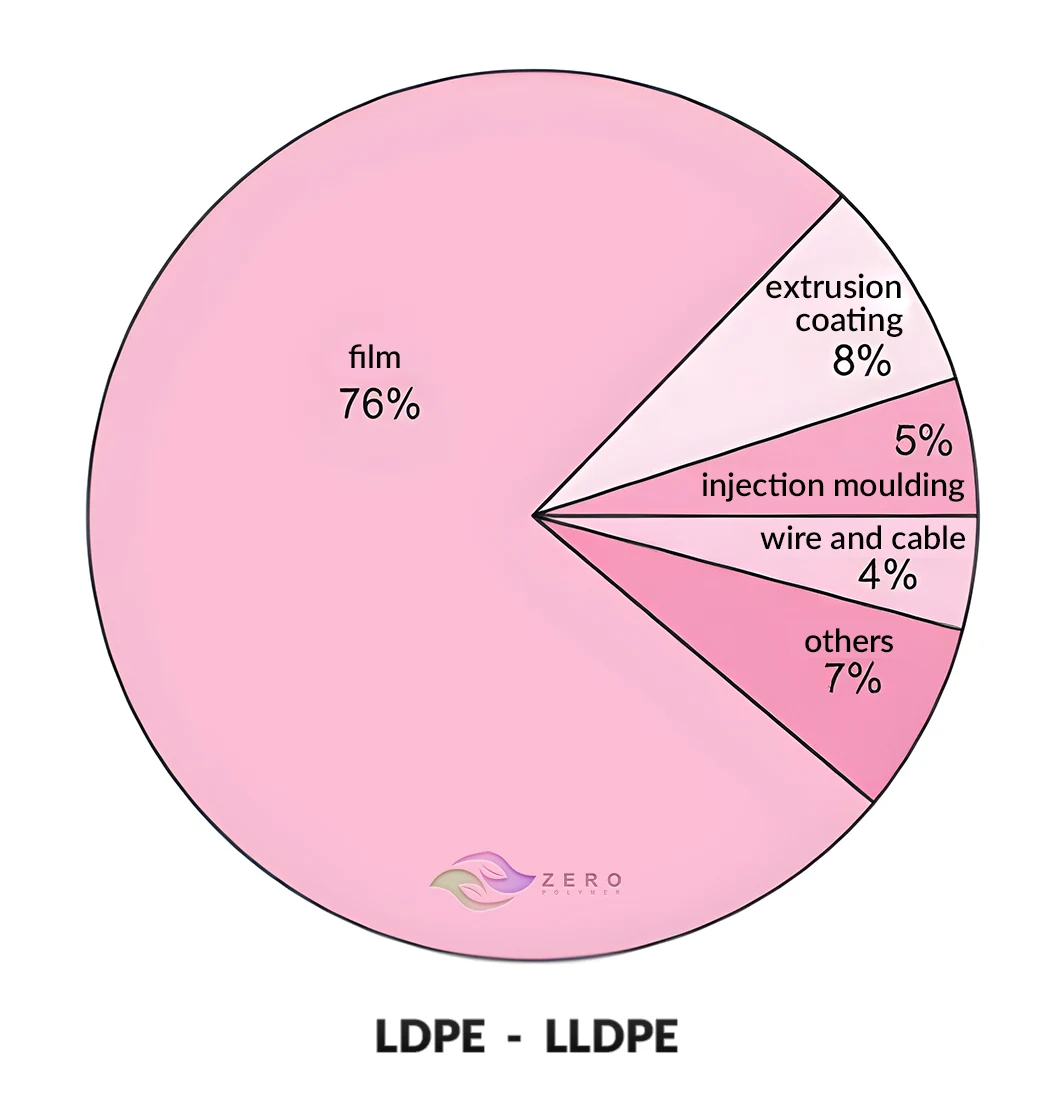

This pie chart provides a visual representation of the different applications of LDPE.

Common Applications of LDPE

- Bags

- Packaging

- Cling wrap

- Clear plastic bags

- Trays

- Frozen food bags

- Pallet wrapping

- Shrink wrapping

- (Juice) Containers

- Water bottles

- Ice cream lids

- Six-Pack Rings for Soda Cans

- Medical equipments

- Tubing

- Plastic drip tape

- Household garbage

- Bakery goods

- Dry cleaning

- Wash bottles

- Extrusion molding

- Laminates

- Prosthetics

This pie chart provides a visual representation of the different applications of LDPE.

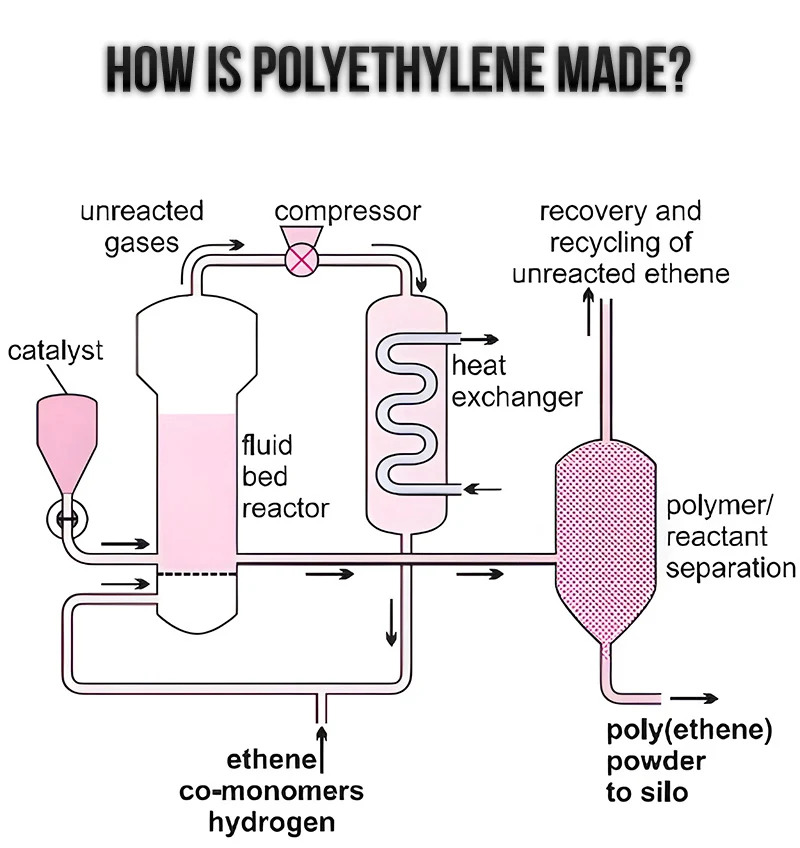

How is LDPE made?

LDPE has unique properties and finds applications in various industries. Understanding its manufacturing process is crucial for assessing its environmental impact.

To produce LDPE, the primary method involves subjecting ethylene gas to high temperatures and pressure in the presence of a catalyst. This forms polymer chains that give LDPE its properties.

The high-pressure process is the most common method for LDPE production. It involves compressing and heating ethylene gas to create a highly reactive environment. A catalyst helps the polymerization reaction, resulting in LDPE formation. This method is efficient, cost-effective, and allows for large-scale production.

The low-pressure process is less frequent among manufacturers but offers better control. It uses a different catalyst and operates at lower temperatures and pressures. While it provides better control, it is more expensive and less commonly utilized compared to the high-pressure process.

Assessing the quality and durability of Polyethylene and LDPE products

When choosing polyethylene and LDPE products, it is important to assess their quality and flexibility. Opting for a product that meets industry standards and has a proven track record of quality can help you save both time and money in the long run.

One effective way to evaluate the quality of these products is by looking into the reputation of the manufacturer. Researching the manufacturer's history and reputation can assist you in determining the reliability of their products. Always look for manufacturers that have a strong industry presence and a track record of producing high-quality products.

The Importance of Product Testing, Certifications, and Warranties

When it comes to choosing the right polyethylene and LDPE products, there are some important factors to consider. One of these is product testing and certifications. You should look for products that have been tested for strength, flexibility, and resistance to various environmental factors. You can also check for certifications such as ISO 9001 or ASTM standards to ensure that the product is of a high quality and reliable.

In addition, it is important to consider the product's warranty or guarantee. A manufacturer that provides a warranty or guarantee for their product is likely confident in its performance and durability.

By taking the time to thoroughly assess the quality of polyethylene and LDPE products, you can make an informed decision that will result in a long-lasting and reliable solution for your specific needs.

Zero Polymer Polyethylene and LDPE Products

At ZPolymer.com, we understand the importance of product testing and certifications. That's why all our polyethylene and LDPE products undergo rigorous testing for strength, durability, flexibility and resistance to environmental factors.

We offer a comprehensive warranty and guarantee for all our products, reflecting our confidence in their long-term durability and performance.

Choose Zero Polymer's polyethylene and LDPE solutions for the perfect fit to meet your specific needs. You can rely on our quality, reliability, and commitment to satisfying our customers. Contact us today to place your order or learn more about our product offerings.

Advancements in LDPE Recycling and Emissions Reduction

It is important to note that the production of LDPE involves certain emissions and waste byproducts, such as volatile organic compounds (VOCs) and greenhouse gases. However, advancements in technology and stricter regulations have resulted in significant reductions in emissions and waste.

According to a life cycle analysis by the U.S. Department of Energy's Argonne National Laboratory, making LDPE with 5% pyrolysis oil instead of virgin oil can result in an 18% decrease in greenhouse gas emissions.

Additionally, current end-of-life practices lead to a further 40% to 50% reduction in GHG emissions when manufacturing pyrolysis-based LDPE. These findings suggest that advanced recycling techniques have the potential to reduce the environmental impact of LDPE production and contribute to global sustainability goals.

Is LDPE Recyclable?

The recycling of Low-Density Polyethylene (LDPE) can be an effective and sustainable technique to reduce greenhouse gas emissions and minimize the environmental impact of plastic waste.

A recent study was conducted by the U.S. Department of Energy's Argonne National Laboratory which showed that advanced recycling methods, such as pyrolysis, can transform post-use LDPE into valuable raw materials. This process has a potential to reduce GHG emissions by 18% to 23% as compared to crude oil-derived plastics.

By using advanced recycling methods, we can repurpose LDPE, reduce dependence on fossil resources, and promote a circular economy. These findings suggest the importance of investing in recycling infrastructure and technologies to achieve a more sustainable and environmentally friendly approach to managing LDPE waste.

Advantages of Using LDPE

Low Density Polyethylene (LDPE) is a popular material due to several advantages it offers:

- Impact resistance: LDPE is known for its high impact strength, making it resilient and able to withstand impact and rough handling. This feature makes it suitable for packaging and protective coatings.

- Moisture resistance and low permeability: LDPE's low water absorption and excellent moisture resistance make it ideal for packaging and storing moisture-sensitive products such as food and waterproof packaging.

- Flexibility and low crystallinity: LDPE's highly branched structure makes it highly flexible and durable, making it perfect for applications like plastic bags and films that require bendability.

- Chemical resistance: LDPE is resistant to a wide range of chemicals, including acids, bases, and solvents. This property makes it ideal for the chemical industry, such as storage containers, chemical tank linings, water pipes and squeeze bottles.

- Cost-effective and economical: LDPE is relatively inexpensive to produce, making it a cost-effective choice for a wide range of applications. Its affordability makes it an excellent choice for packaging and disposable products such as lightweight carrying containers, plastic bags, and cling wraps.

- Widely recyclable: LDPE is 100% recyclable and can be reused with relative ease, making it an environmentally friendly option for various industries.

These benefits, combined with its odorless, sterile, and watertight properties, make LDPE an attractive option for a broad range of products, including food-safe bagging, packaging materials, and various industrial applications.

What is the Difference Between LDPE and HDPE?

LDPE and HDPE are two of the most common types of plastic on the market. They have a lot in common and a lot that separates them too.

Both have low material weight and high impact strength, and are highly recyclable. However, LDPE is much softer and more flexible than HDPE, has a lower melting point, and is more transparent. On the other hand, HDPE is more rigid and durable, has better chemical resistance, and can withstand more brutal temperatures than LDPE.

While both are recyclable, they cannot be recycled together. LDPE is classified under recycling number 4, and HDPE is recycling number 2.

Companies commonly use LDPE for plastic bags, packaging films, and water pipes. They use HDPE for chemical drums, jerricans, carboys, toys, picnicware, household and kitchenware, cable insulation, carrier bags, and more.

Zero Polymer: Your Premier Choice for Reliable Supply

At Zero Polymer Trading Company, we have a long history of operating within the global trade sector and have built a reputation for offering top-notch exports to our clients. With a presence in every corner of the globe, we work closely with reliable business partners worldwide to ensure our customers receive the most favorable commercial terms possible.

Why Choose Zero Polymer Trading Group?

- Diverse Core Activities: Offering a wide range of services, from supplying raw materials and engineering compounds to providing specialized services and technical collaboration in various industries.

- Innovative Solutions: Dedicated to delivering innovative solutions across automotive, household appliances, electrical sectors, and more.

- Global Presence: With extensive exporting and importing capabilities, we ensure seamless international transactions, providing customs clearance and transportation services worldwide.

- Proven Achievements: Our milestone of establishing direct communication with producers reflects our commitment to product improvement and being a leading producer of polymer materials.

- Environmental Commitment: Focused on environmental preservation, we lead in the production of biodegradable polymers, contributing to a waste-free world.

- Comprehensive Services: Offering a one-stop location for polymer research, testing, and manufacturing processes, we provide support, after-sales services, and training courses in commerce and exports.

- Youth Employment: Committed to sustainable development, we emphasize youth employment and make significant contributions to research and development for technological advancements.

- Mission and Values: Our social mission, effective roles in professional organizations, and influential contributions to conferences align with our values of entrepreneurship, knowledge emphasis, quality commitment, and innovation.

- End-to-End Services: From consultancy and financing to procurement, packaging, inspection, laboratory testing, and timely and reliable delivery, we ensure a comprehensive suite of services for our customers.

- Sustainable Practices: Our commitment to sustainability extends to responsible development, respect for employees, and the creation of a healthy competitive environment in business.

What Sets Us Apart

Choosing Zero Polymer means aligning with a company that not only meets your immediate needs but also shares a commitment to excellence, innovation, sustainability, and social responsibility in the polymer industry.

Our valued customers are our top priority. We strive to make the process of acquiring a wide range of chemicals and polymers as convenient as possible.

Whether you're searching for basic raw materials or sophisticated petrochemical goods, please don't hesitate to reach out to us. Our skilled staff at Zero Polymer will do their utmost to meet your requirements.

Get in Touch

At ZPolymer.com, we value your inquiries and feedback. Our team is here to assist you with any questions or requests you may have. Whether you need information about our products, pricing, or collaboration opportunities, we are dedicated to providing prompt and reliable support.

Reach out to us today and discover how we can meet your polymer needs with our exceptional solutions.