What Is LLDPE?

Linear low-density polyethylene (LLDPE) is a type of polymer that can change into different shapes and is widely used for packing objects. Ethylene and alpha-olefin form it using a particular process.

LLDPE is distinguished from other types of polyethylene by the short branches of its molecular structure. This type of material can form highly strong sheets with a high ability to stretch. Flexibility, puncture resistance, high tensile strength, and UV resistance are the prime properties of this material.

These are the attributes through which LLDPE is well-suited for various applications such as pallet stretch film, garbage bags, hopping bags, and floor tiles. Given that, it can be processed using blow molding and injection molding.

LLDPE would not create any harmful effects on human health even if it comes in direct food, and also tends to be nontoxic otherwise. Since LLDPE isn't bio-friendly it provides low mnemonic retention. Any kind of inhalation should be avoided because it leads to an uneasy feeling in the throat especially during the processing of LLDPE.

With each coming year, the demand and revenue for LLDPE are projected to spike immensely, a testament to their efficacy across different industries.

5 Types of PE

Linear low-density polyethylene (LLDPE) is one of the five main groups of polyethylene, each with different properties and uses. The other four groups of polyethylene are low-density polyethylene (LDPE), high-density polyethylene (HDPE), very low-density polyethylene (VLDPE), and ultra-high molecular weight polyethylene (UHMWPE).

LLDPE is commonly used in a wide range of applications due to its high strength, impact resistance, and ability to withstand punctures. It is valuable for its ability to make thinner films without compromising strength. Therefore, it is suitable for products such as plastic bags, stretch wraps, toys, and flexible tubing.

5 types of PE

Linear low-density polyethylene (LLDPE) is one of the five main groups of polyethylene, each with different properties and uses. The other four groups of polyethylene are low-density polyethylene (LDPE), high-density polyethylene (HDPE), very low-density polyethylene (VLDPE), and ultra-high molecular weight polyethylene (UHMWPE).

LLDPE is commonly used in a wide range of applications due to its high strength, impact resistance, and ability to withstand punctures. It is valuable for its ability to make thinner films without compromising strength. Therefore, it is suitable for products such as plastic bags, stretch wraps, toys, and flexible tubing.

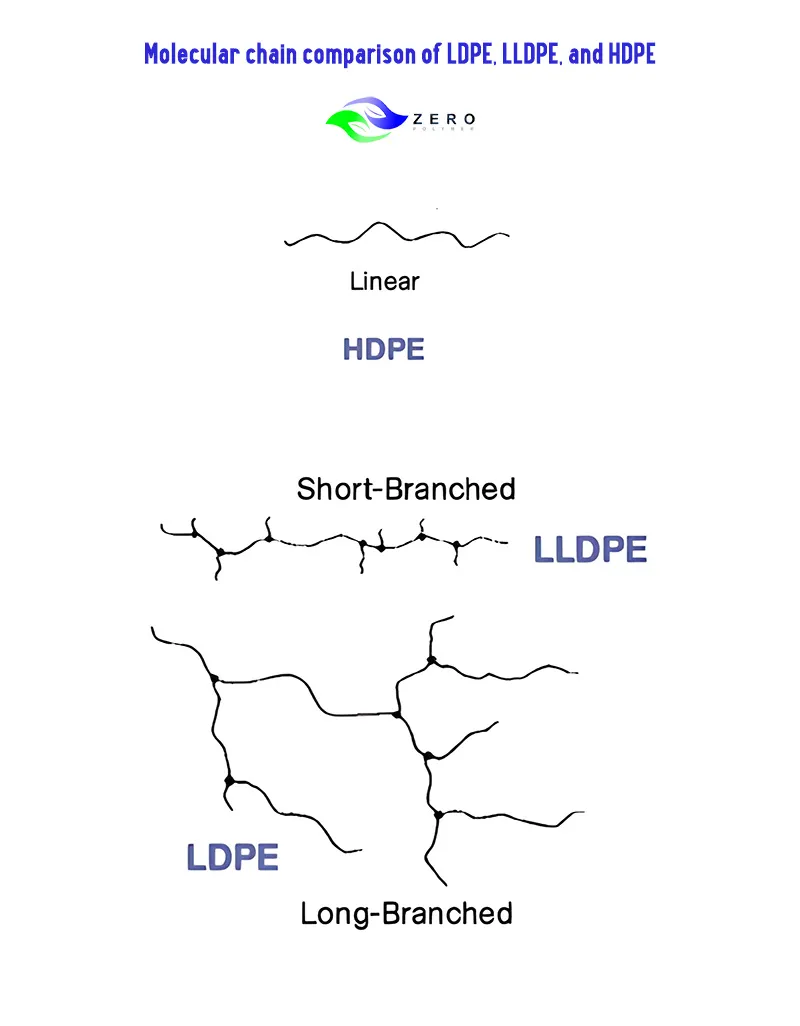

What is the structure of LLDPE?

Linear low-density polyethylene is a semi-crystalline plastic. It has many short branches on its main chains that help it bend more easily. This means that these straight chains do not get tangled up like LDPE and HDPE. The image shows the gap between LLDPE and other common types of polyethylene.

LLDPE plastic is usually made from one of the three different co-monomers called alpha-olefins. These are described below.

Octene: This is the best-quality co-monomer, so it costs much more than others. The octene co-monomer has the biggest side chains.

Hexene: This material, also known as high-grade co-monomer, provides a balanced mixture of octene and butene.

Butene: Because it's cheaper, butene is used the most for making normal plastic stuff. The butene co-monomer has the shortest branches.

A mix of the mentioned co-monomers is also used to change LLDPE plastic properties. The most common mix uses butene and hexene together.

Properties and Characteristics of LLDPE

Linear low-density polyethylene (LLDPE) is a type of polyethylene with a substantially linear structure and significant numbers of short branches. LLDPE has unique properties that make it a popular choice for various applications. Here are some of the properties and characteristics of LLDPE:

- Higher tensile strength, impact resistance, and puncture resistance than LDPE

- Very flexible and elongates under stress

- Can be used to make thinner films with better environmental stress cracking resistance

- Puncture-resistant and resistant to oxidation

- Good resistance to chemicals

- Good electrical properties

- Unique melt flow properties

- Less shear sensitive than LDPE due to its narrower molecular weight distribution and shorter chain branching

- Stiff in shear and soft in extension

- Not as easy to process as LDPE, has lower gloss, and narrower range for heat sealing

- Good toughness relative to other products

- Good water vapor and alcohol barrier properties

- Poor barrier to oxygen, carbon dioxide, and many odor and flavor compounds

Manufacturers produce LLDPE as granules or powder. They typically add various additives to them, including anti-block agents, antioxidants, and UV stabilizers.

What Are the Mechanical Properties of Linear Low-density Polyethylene?

The following are typical mechanical characteristics of LLDPE plastic. These properties are specific to the most widely used version of LLDPE plastic, which includes butene in its formulation.

| Material Property | Value |

|---|---|

|

Density (g/cm3) |

0.92 |

|

Tensile Strength (MPa) |

20 |

|

Flexural Modulus (GPa) |

0.35 |

|

Elongation at Break (%) |

500 |

|

Maximum Operating Temperature (C) |

50 |

|

Heat Deflection Temp @ 0.45 MPa (C) |

45 |

|

Heat Deflection Temp @ 1.80 MPa (C) |

37 |

|

Plastic Melting Point (C) |

220 - 260 |

|

Mold Shrinkage (%) |

3 |

What is LLDPE used for?

LLDPE is a widely used material in various industries due to its unique properties. It is flexible, stretchable, and resistant to chemicals, making it suitable for multiple applications.

Here are some examples:

Packaging Films: LLDPE is frequently used for packaging products such as snacks, frozen foods, and beverages. Its flexibility and stretchability make it ideal for wrapping irregularly shaped items and protecting against moisture, dust, and other contaminants.

Industrial Liners: LLDPE is an excellent choice for lining storage tanks, ponds, and other containment systems due to its chemical resistance. It helps prevent leakage and contamination of hazardous substances, ensuring the safety and integrity of the stored materials.

Geomembranes: LLDPE geomembranes act as barriers to prevent the seepage of liquids and gases in landfills, reservoirs, and other construction projects. Its high puncture resistance and flexibility ensure long-term durability and protection.

Agricultural Films: LLDPE films are used for mulching, greenhouse covers, and silage bags. They help conserve water, control weed growth, and protect crops from pests and extreme weather conditions. The UV resistance and tear resistance of LLDPE make it suitable for outdoor applications, ensuring the longevity of agricultural structures.

Consumer Goods: LLDPE is used in the manufacturing of various consumer goods, such as toys, containers, and household products. Its flexibility and impact resistance make it suitable for applications where durability and safety are important.

Pipe and Tubing: LLDPE pipes and tubing are used in industries such as plumbing, irrigation, and gas distribution due to their excellent flexibility and resistance to chemicals.

Wire and Cable Insulation: LLDPE is used as insulation for wires and cables due to its electrical properties and flexibility, ensuring the safe and efficient transmission of electricity.

Medical Applications: LLDPE is used in the medical field for applications such as medical packaging, tubing, and disposable medical devices. Its biocompatibility and sterilizability make it suitable for use in healthcare settings.

Some of its most common uses are mentioned below.

Common Applications of LLDPE

- Packaging snacks, frozen foods, beverages, and multi-pack beverages

- Storage tanks, ponds, and containment systems

- Mulching, greenhouse covers, and silage bags

- Toys

- Buckets and containers

- Pipes and tubing

- Medical packaging, tubing, and disposable medical devices

- Grocery bags

- Trash bags

- Shrink wrap film

- Multi-pack beverage shrinkwrap

- Geomembranes

- Injection molding

- Rotomolding

- Pond liners

- Blended films for added flexibility and strength

- Waste bins

- Refrigerated appliances

- Fuel tanks

- Chemical tanks

- Pipe and wire and cable coatings

- Plastic wrap

- Stretch wrap

- Pouches

- Covers

- Lids

- Covering of cables

- Flexible tubing

Is LLDPE Recyclable?

LLDPE (Linear Low-Density Polyethylene) is a type of plastic that is recyclable. However, the recycling rate for LLDPE is generally lower than that of other plastics.

Manufacturers use LLDPE in a blend with other types of plastic, which can make recycling more challenging. Some of the typical recycled LLDPE applications are gaylord liners and industrial garbage bags.

Recycling LLDPE involves several steps, such as shredding, separation, granulation, washing, drying, and bagging. The recycled material can be used in various industries, including packaging, automotive, and construction. For example, recycled LLDPE can be used to make carrier bags, shrink films, and other packaging materials in the packaging industry. In the automotive industry, it can be used to make bumpers and other components.

However, there are some challenges in recycling LLDPE, such as the lack of recycling facilities and difficulties in sorting and processing the material.

Despite these challenges, LLDPE is a commonly recycled material, and its recycling process helps reduce waste and conserve valuable resources.

Assessing the quality and durability of Polyethylene and LLDPE products

When choosing polyethylene and LLDPE products, it is important to assess their quality and flexibility. Opting for a product that meets industry standards and has a proven track record of quality can help you save both time and money in the long run.

One effective way to evaluate the quality of these products is by looking into the reputation of the manufacturer. Researching the manufacturer's history and reputation can assist you in determining the reliability of their products. Always look for manufacturers that have a strong industry presence and a track record of producing high-quality products.

The Importance of Product Testing, Certifications, and Warranties

When it comes to choosing the right polyethylene and LLDPE products, there are some important factors to consider. One of these is product testing and certifications. You should look for products that have been tested for strength, flexibility, and resistance to various environmental factors. You can also check for certifications such as ISO 9001 or ASTM standards to ensure that the product is of a high quality and reliable.

In addition, it is important to consider the product's warranty or guarantee. A manufacturer that provides a warranty or guarantee for their product is likely confident in its performance and durability.

By taking the time to thoroughly assess the quality of polyethylene and LLDPE products, you can make an informed decision that will result in a long-lasting and reliable solution for your specific needs.

Zero Polymer Polyethylene and LLDPE Products

At ZPolymer.com, we understand the importance of product testing and certifications. That's why all our polyethylene and LLDPE products undergo rigorous testing for strength, durability, flexibility and resistance to environmental factors.

We offer a comprehensive warranty and guarantee for all our products, reflecting our confidence in their long-term durability and performance.

Choose Zero Polymer's polyethylene and LLDPE solutions for the perfect fit to meet your specific needs. You can rely on our quality, reliability, and commitment to satisfying our customers. Contact us today to place your order or learn more about our product offerings.

Advantages of Using LLDPE

LLDPE is a type of polyethylene that provides various benefits that make it a preferred choice in many applications. Some of the key advantages of using LLDPE include:

Higher Chemical Resistance: LLDPE has better resistance to chemicals than LDPE. That makes it suitable for applications where exposure to various chemicals is a concern.

Better Mechanical Characteristics: LLDPE offers improved mechanical properties at both low and high temperatures, making it a versatile material for a wide range of applications.

High Resistance to Puncture and Tearing: When companies utilize LLDPE in film production, it demonstrates increased resistance to puncture and tearing. Therefore, it is suitable for packaging and other related applications.

Superior Flexibility and Tensile Strength: LLDPE's superior flexibility and tensile strength make it more resistant to impact, puncture, and environmental factors. That makes it an ideal choice for products that require these properties.

Narrower Molecular Weight Distribution: LLDPE has a narrower molecular weight distribution than LDPE. Therefore, it contributes to its unique properties and performance advantages.

High Surface Gloss and Crack Resistance: LLDPE has high surface gloss and resistance to cracking. As a result, it enhances the aesthetic and functional qualities of products made from this material.

Good Environmental Stress Cracking Resistance: LLDPE exhibits good resistance to environmental stress cracking. Thus, it is suitable for outdoor applications and other challenging environments.

UV Resistance: LLDPE retains its strength when exposed to UV radiation, making it suitable for outdoor and UV-exposed applications.

LLDPE's unique molecular structure includes shorter branches, providing high tensile strength and impact resistance. This makes it a preferred resin for modern applications. In addition to its advantages, LLDPE finds wide-ranging uses in various industries.

LLDPE is commonly used in a wide range of products and applications, including packaging, stretch wrap, ice bags, and various film applications. Its versatility and combination of properties make it a popular choice for many ends uses, including food and beverage packaging, toys, bins, buckets, plastic tanks, and various types of films, such as general-purpose, stretch, garment packing, and agricultural films.

What is the Difference Between LLDPE, LDPE and HDPE?

LLDPE (Linear Low-Density Polyethylene), LDPE (Low-Density Polyethylene), and HDPE (High-Density Polyethylene) are three types of plastics that are widely used in various applications. Although these plastics share some similar properties, there are also significant differences between them.

Polyethylene is a widely used plastic with different types, including LDPE, LLDPE, and HDPE. LDPE is more flexible and impact-resistant than HDPE, while HDPE is stronger but more brittle than LDPE. LLDPE is a linear polymer with short branches, making it more flexible and puncture-resistant than LDPE. It is also used to make thinner films with better environmental stress-cracking resistance. HDPE is the most durable and chemically resistant, but it is less flexible than LDPE and LLDPE. It is commonly used in products such as plastic bottles, containers, and pipes.

Main Differences

One of the main differences between LLDPE, LDPE, and HDPE is their molecular structure. LLDPE is a copolymer of ethylene and another longer olefin, which gives it a coiled shape and allows it to stretch more than LDPE or HDPE. LDPE is a homopolymer of ethylene, meaning it is made up of only ethylene molecules. HDPE is also a homopolymer of ethylene, but it is made up of longer ethylene molecules, which makes it more rigid and less flexible than LDPE or LLDPE.

Another difference between LLDPE, LDPE, and HDPE is their density. HDPE is the most dense of the three, with a density of around 0.96 g/cm3, while LDPE and LLDPE have densities of around 0.92 g/cm3 and 0.93 g/cm3, respectively. The higher density of HDPE means that it is more resistant to compression and is often used in applications where high rigidity is required.

The differences in molecular structure and density between LLDPE, LDPE, and HDPE also affect their mechanical properties. HDPE is generally stronger and more resistant to compression than LDPE or LLDPE, while LDPE and LLDPE are more flexible and can withstand higher stress levels.

Despite their differences, LLDPE, LDPE, and HDPE are all commonly used in a wide range of applications, including packaging, pipes, and containers. LLDPE is often used in films and linings for packaging applications, while LDPE is used in packaging such as bottles and shrink wrap. HDPE is used in pipes and containers due to its resistance to compression and its ability to withstand high stresses.

Zero Polymer: Your Premier Choice for Reliable Supply

At Zero Polymer Trading Company, we have a long history of operating within the global trade sector and have built a reputation for offering top-notch exports to our clients. With a presence in every corner of the globe, we work closely with reliable business partners worldwide to ensure our customers receive the most favorable commercial terms possible.

Why Choose Zero Polymer Trading Group?

- Diverse Core Activities: Offering a wide range of services, from supplying raw materials and engineering compounds to providing specialized services and technical collaboration in various industries.

- Innovative Solutions: Dedicated to delivering innovative solutions across automotive, household appliances, electrical sectors, and more.

- Global Presence: With extensive exporting and importing capabilities, we ensure seamless international transactions, providing customs clearance and transportation services worldwide.

- Proven Achievements: Our milestone of establishing direct communication with producers reflects our commitment to product improvement and being a leading producer of polymer materials.

- Environmental Commitment: Focused on environmental preservation, we lead in the production of biodegradable polymers, contributing to a waste-free world.

- Comprehensive Services: Offering a one-stop location for polymer research, testing, and manufacturing processes, we provide support, after-sales services, and training courses in commerce and exports.

- Youth Employment: Committed to sustainable development, we emphasize youth employment and make significant contributions to research and development for technological advancements.

- Mission and Values: Our social mission, effective roles in professional organizations, and influential contributions to conferences align with our values of entrepreneurship, knowledge emphasis, quality commitment, and innovation.

- End-to-End Services: From consultancy and financing to procurement, packaging, inspection, laboratory testing, and timely and reliable delivery, we ensure a comprehensive suite of services for our customers.

- Sustainable Practices: Our commitment to sustainability extends to responsible development, respect for employees, and the creation of a healthy competitive environment in business.

What Sets Us Apart

Choosing Zero Polymer means aligning with a company that not only meets your immediate needs but also shares a commitment to excellence, innovation, sustainability, and social responsibility in the polymer industry.

Our valued customers are our top priority. We strive to make the process of acquiring a wide range of chemicals and polymers as convenient as possible.

Whether you're searching for basic raw materials or sophisticated petrochemical goods, please don't hesitate to reach out to us. Our skilled staff at Zero Polymer will do their utmost to meet your requirements.

Get in Touch

At ZPolymer.com, we value your inquiries and feedback. Our team is here to assist you with any questions or requests you may have. Whether you need information about our products, pricing, or collaboration opportunities, we are dedicated to providing prompt and reliable support.

Reach out to us today and discover how we can meet your polymer needs with our exceptional solutions.